Fellwalker Bolts

From Compendum Caidis

Jump to navigationJump to search

Fellwalker Bolts from the SCA Armored Combat Marshal’s Handbook

- a. The “Fellwalker design” is approved for crossbows only (heavy and light)

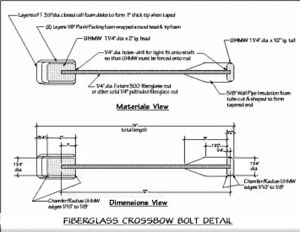

- b. The shaft is of solid fiberglass of between .25 inch (6.5 mm) and .375 (that is, 3/8) inch (9.5 mm) diameter. Fiberglass shall be of good quality, defined as significant bending pressure as applied by a marshal not causing the shaft to break.

- c. The core is made from UHMW rod of at least 1.25 inches (31.8 mm) diameter with a hole drilled in it to accept the shaft.

- d. The shaft hole must be at least 1 inch (25.4 mm) deep, and there must be at least 1 inch (25.4 mm) of UHMW in front of the shaft.

- e. The striking surface must have at least 1 inch (25.4 mm) and at most 1.25 inches (31.8 mm) of padding (with progressive resistant give) after taping and be at least the diameter of the blunt.

- f. The head must have padding (with progressive resistant give) that extends from the tip of the padding to at least .5 inch (12.7 mm) over the UHMW that brings the total diameter of the head to at least 1.5 inch (3.8 cm) after taping.

- g. The tail end must have a disk of UHMW installed that is at least 1.25 inches (31.8 mm) diameter, at least .5 inch (12.7 mm) thick, and drilled at least .25 inch (6.5 mm) deep to accept the shaft. It must be attached securely via tape, glue, cable ties, etc. The method does not matter as long as it is securely attached and will not come off during normal use. This will be tested by Marshals by grabbing and pulling on the APD with moderate force while twisting it slightly. If it detaches or moves lengthwise along the shaft, then it fails.

- h. The shaft must be covered from behind the blunt, to the front of the anti- penetration device (APD), in a sturdy tear-resistant tape, such as strapping, electrical, or duct tape.

- i. All sharp edges must be eased.

Notes by Morgan Fellwalker:

The 2018 SCA Marshals Handbook doesn't include the correct construction specs for Fellwalker Crossbow Bolts. A 12" shaft length was REQUIRED because it's a deliberate design point addressing safety issues:

- 1. It makes every bolt coming through inspection the same length, allowing marshals to immediately recognize an illegally constructed bolt.

- 2. It makes marshals immediately aware of a dangerous bolt where the shaft is coming loose (which will result in the shaft sliding and breaking the tape on the head or tail upon impact).

- 3. It makes marshals immediately aware of a dangerous bolt where the shaft is punching through the UHMW or the UHMW is drilled too deeply and doesn't have a solid 1" of material in front of the shaft.

- 4. Arbitrarily longer and shorter shafts result in the bolt cartwheeling in flight with a high likelihood of hitting someone tail end first or across the shaft.